We will review our thermal bar code printer product family and typical industrial printing applications. Product Marketing Director Andy Scherz goes in depth on how thermal bar code printers work. In addition to explaining key differences between direct thermal and thermal transfer technology. Andy also explains what applications are more appropriate for thermal resin ribbons or thermal wax ribbons and which applications are more appropriate for thermal transfer bar code printers.

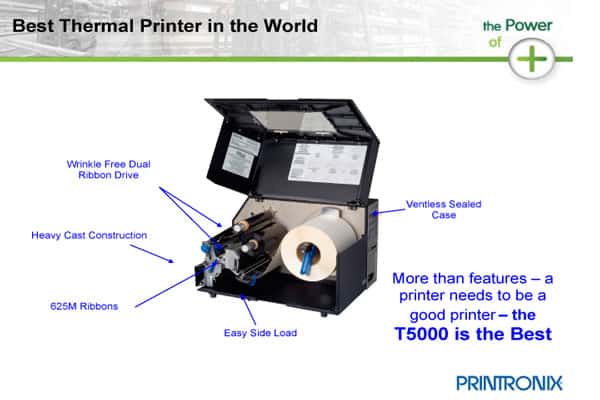

So let me just talk a little bit about the products that we offer specifically today. Today in our class we are occupying what they call a stationary composed of mid-level and above. And we have two major families, the T5000r is what I would call the flagship of the line. It’s in the high-performance class in the highest price category of the class. We have three basic sizes like I talked about in the classifications, we have a four-inch a 6 inch and an 8 inch, 200 and 300 dpi, RFID upgradable, 10/8 IPS depends on the speed and resolution 200 dpi is 10 IPS and 300 dpi is 8 IPS. I put in the blue here a little bit of a note because what’s interesting is I don’t think people generally realize how fast a thermal printer is. That printer is 54 page a minute. That blows the doors off almost any cut sheet laser printer. I don’t think people really think about that, about how fast these guys really are, but they are stunningly fast. This guy has a 625 meter ribbon so that ribbon I showed you that uses those images, we are unique in that category, 625 meters, most of our biggest competitors are up around 450 meters, and you know, the longer the supplies, the more you can go without having to change it out. We have a dual motor drive that’s all metal construction, really, it’s a super durable mechanism.

Then we have our T4M midrange, this one we have a 4 inch width only. 200 and 300 dpi, also RFID upgradable, 10 IPS for both 200 and 300 dpi, again an amazing 54 page a minute. This one uses a 450 meter ribbon, and it has a different motor drive, kind of a more traditional motor and clutch assembly like that, and I’ll talk about that motor drive a little more when I talk specifically of the T5000r. And it’s again mostly metal, not all here, but if you look the specs look similar but you’re looking at almost a $1000 differential between those guys. Again, it’s durability, not so much just a raw speed of something like that that drives this.

So, how do we win in thermal? What is our unique advantage? How can we beat other people in this marketplace? So the first thing is is the lineage of our line, Printronix through years and years have established an unbelievable brand for durability and reliability, just dealing with us as a Company, and the T5000 line is really a baby of that lineage.

And that’s really really important, what I try to show on this chart here is that in the marketplace a lot of times you have products that sort of overlap each other. Kind of similar in specs, but there is a distinct market out there for premium class products, and really Printronix represents that premium class product. There might be comparable models out there, but when you get really get down to the true intrinsic value of the printer, the Printronix is ahead.

Why?

The printer is just a very very solidly designed printer, if you look at it, and I’ll show you the real printer in a second, it’s all die cast, you can see these shafts, all metal, this is all very very heavy construction, I mean even if you are not that mechanically inclined, if you look at this printer, you just go “that thing looks pretty tough”, in fact one of our biggest salesman, and I mean that as in BIGGEST salesman in size loves to take the printer and stand on it as part of his demo, just to demonstrate the sheer ruggedness of the printer.

Also it has a very unique situation here when you open the thing up, it opens all the way up and it’s very easy just to load your supplies in here. So the idea is it’s a very clean assembly, it’s very easy to put your ribbons in their, very easy to put the media in their, it’s all durable and runs really really tight. We do something unique here, what we have is our ribbon, the ribbon starts off on here and as you use it it goes up on the pickup spool, and what we do is, we have a motor here and a motor here, and what that means is we use one motor to drive and one motor acts like a break which keeps the tension on this ribbon very even. So go home and get a big piece of Saran Wrap and pull on it, what you’re going to see is, it’s going to make all kinds of little wrinkles, it’s not going to pull and looked like a nice perfect she of glass,it’s going to look all wrinkly and everything like that. In the thermal transfer roll, if that ribbon wrinkles it’s going to leave the defect on the print. So your ability to make that tension neat and even and smooth is a huge effort of the design, and Printronix is very very distinctive in using two motors to very carefully decide how much to pull, how much to break, how much tension to make this ribbon not wrinkle and make that print quality very very good, Printronix is unique, we are the only one with that kind of mechanism in there.

The second thing is, when I talked earlier about the 4204, I talked about investing in the controllers, that the electronics behind these printers is a really central part of the value. One of the most important things that we’ve done is we’ve actually gone out and we have emulated almost every single major competitive printer out there, Zebra, TEC, Intermec, Sato, Datamax, Monarch, IER, this one printer can drop into place of any of those guys.

So you can take any of these competing products, grab a T5000r and put it in there, grab a T4 and put it in there. This is very important to people because a lot of the time, IT departments will want to standardize on one piece of equipment so that they know how to fix it, they don’t have to keep all kinds of different spare parts, they don’t have to have different configurations for doing different things, but nowadays in business it’s not so neat, we have all kinds of mixed marriages you have Printronix coming together with TallyGenicom, you might have some equipment from one company and equipment from another and now you’ve got this mixed family, we gonna do? One guy was using zebra and the other guy was using DataMax, well with Printronix you can buy just one printer and it can plug-in to replace all of those guys, this is really distinctive for us, its the only printer out there with this suite of emulations like that, very distinctive.